Do you ever find it hard to shop for the men in your life? Thinking up good gifts for men always seem to be harder, amirite?

I always find it super hard to shop for Mike, so this year I’m getting a bit of a head start. These are some of my ideas for perfect gifts for those hard-to-shop-for people in your life, featuring plenty of cozy feels! They’re not just for men, but they definitely appeal to those who like a more masculine aesthetic: leather, whiskey, and the great outdoors.

Even though I’m looking for gifts that appeal to men, the theme for this year, according to me anyway, is cozy. I mean, it’s always cozy, but this gift guide feels particularly so. We’re featuring a mix of items that you can use on a crisp, cold day picnic, a bunch of our favorite kitchen things, cozy indoor activities, and some things that are just cute!

Gifts for men who are outdoorsy

Mini Concrete Fire Pit

If you or someone you love is missing campfires because it’s winter, get this amazingly cute tabletop fire pit. We have one and I love it so much. You fill it up with isopropyl alcohol (sold in the pharmacy) and just light it up for instant campfire feels. You can even roast marshmallows on it. We use ours on our deck and have brought it to the park and the beach and it’s such a cheery, warm table topper. Honestly I kind of want another one because I love it so much. Really, it’s the perfect gift for the pyro, s’more lover, or hipster friend in your life. [Amazon]

Camp Loveseat

If you ever go tailgating, camping, to the park, or just want to cozy up to something, this is the portable chair for you! It’s a camp loveseat and believe me when I say that it’s super duper comfortable. It’s a great gift for anyone who spends a lot of time at outdoor sports, especially if you pair it with some hot hands (air activated hand warmers). [Amazon]

Mini Portable Butane Stove

If someone you know is interested in hosting a Korean barbeque or hot pot party this is the cutest little butane stove. It’s also pretty portable so you can take it camping with you so it’s not just an use it at home kind of gift. I love how it comes in different colors. It’s also perfect for the friend who wants to fim their own cafe at home YouTube videos :) If you want to gift an induction cook top instead, we have and love this one. [Amazon]

Gifts for men who like to be in the kitchen

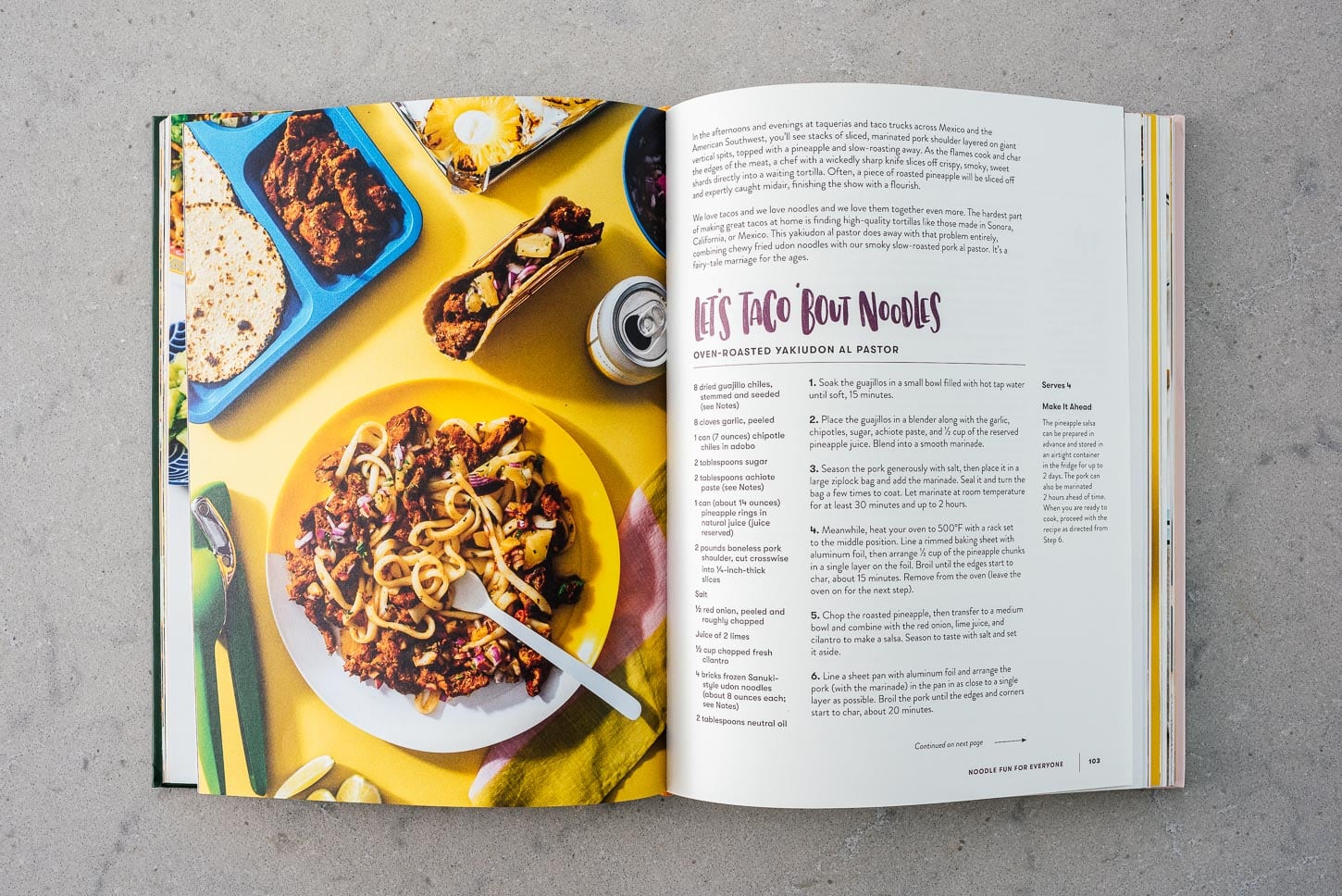

That Noodle Life

This is the BEST gift for noodle lovers and I’m not just saying that because we wrote it. It’s bright and fun and has some of the best photos of noodles out there. I can say that because I love Mike’s photography and I think it’s some of his best. They’re also some of our best noodle recipes. Try it, you won’t regret it. There are quick recipes for weeknights, recipes to flex your cooking skills, and recipes that will introduce you to new flavors that will quickly become your favorites. Noodles are the ultimate comfort food and this is a book that will comfort you and whoever you gift it to. [Amazon]

Milk Frother

If you’re looking for a stocking stuffer, a milk frother is perfect! I know what you’re thinking, no one you know even needs to froth milk. But the beauty of a milk frother is that it’s a mini electric whisk – one that that help you emulsify salad dressings, whisk eggs so they’re perfectly smooth, and make individual portions of whipping cream. I use mine all the time, it’s truly one of my underrated workhorses in the kitchen. If you have a matcha lover in your life, someone who takes collagen or protein powder, or enjoys lattes, they will love this small, thoughtful gift. PS – milk and oat milk froths up amazingly with micro foam with this whisk in particular. [Amazon]

East Fork Pottery

I’m a huge pottery fan and I LOVE East Fork. Everyone needs beautiful bowls to eat out of and if you want to treat a loved one, I recommend their rainbow set created in partnership with Molly Yeh. It’s fun, poppy, and colorful just like Molly herself. If you want something smaller, I think their small mug is the perfect size and shape.

Balmuda the Toaster

Do you have a toast lover in your life? If so, treat them (or yourself) to the BEST toaster out there. Last year Mike surprised me with a Balmuda (I’ve been dreaming of one forever) and I was so surprised and touched. We had Christmas day toast and it was magical. Part of the magic is that Balmuda uses steam technology to make the inside of your toast fluffy and moist while toasting the outside to a golden crisp. If you’ve ever watched Emily of salmon rice bowl fame make toast on Tiktok, this is the toaster she uses. [Amazon]

Bagna Cauda Warmer

Have you had bagna cauda? It’s an Italian anchovy garlic dip that’s served in a special warming dish with seasonal raw and cooked vegetables. It’s a cozy, communal appetizer and so much fun to prepare and eat. You don’t technically need a bagna cauda warmer, but it adds to the atmosphere. I think a cute present would be a warmer with a handwritten recipe and a promise to enjoy a night of bagna cauda and wine together. Plus, you can use your warmer for cheese or chocolate fondue as well! [Amazon]

Tinned Fish

Conservas (fancy tinned fish and seafood) is so popular right now. There are so many gorgeous delicious tins of seafood out there and they make a cute stocking stuffer or gift basket. Gift one or many tins to the seafood lover in your life and watch their eyes light up. Conservas can go from low-end to high and as with most food items, are a personal choice. A good place to start is: Portuguese sardines in olive oil, roasted garlic mackerel, spicy wild Portuguese calamari, wild Spanish cockles in sea salt brine, or smoked mussels in olive oil and broth. Add a Spanish hot sauce, some chips, and your gift recipient can have a conservas party. Bonus, these little wooden handled sardine forks are perfect for gifting alongside. PS – extra points if you get them these Spanish potato chips.

Gifts for men who like cozy feels

Holiday Puzzles

Come winter, we love putting out a puzzle on a table and spending the month of December slowly completing it. Glasses of wine, small nibbles, good music, deep conversations, and puzzling is what growing up is all about. Call it boring if you will, but puzzling is SO relaxing. Gift this to the stressed out person in your life. Oh, but only if they don’t get anxiety about leaving things unfinished. Some of our favorites are vintage bucolic food themed puzzles, especially those by Charles Wysocki like this Vermon Maple Tree one, and this Christmas one. We also like the vintage New Yorker covers like this or this. Lastly, these winter pups and cute cats are absolutely adorable.

Tortilla Blanket

Everyone dreams of being a burrito, right?! Make a loved ones’ dreams come true with this extra cozy burrito blanket! It’s double sided, super fuzzy and soft, and really warm. I have one and I LOVE it so much. To be honest, I have two. It’s quirky, cozy, and the burrito lover in your life will love it. [Amazon]

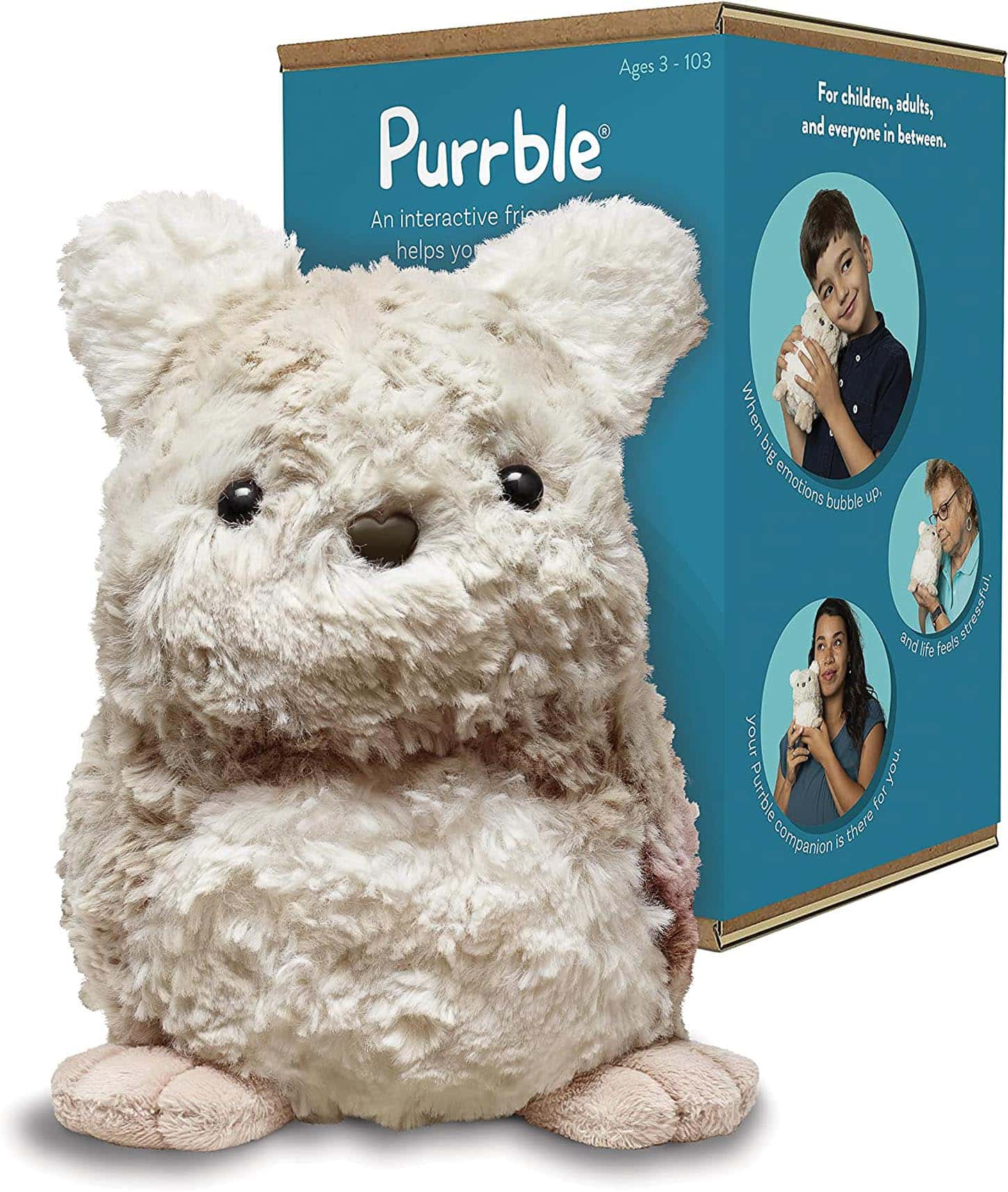

Purrble

This lil guy is on my actual holiday wishlist because I’m allergic to cats and I dream of a little furry that can purr in my arms. Apparently this plush companion is great for soothing you and well, it’s just so CUTE! I think it’s a great gift for everyone, even for people whom you don’t think like plushies. We can all use a little more softness in our lives. [Amazon]

Alright, that’s it. Hope you found something interesting that you haven’t thought of gifting! Happy holiday season!

xoxo steph